Red Lodge Clay Center – Short-Term Resident 2011, (AIA) 2013

Tyler Lotz’s sculptures and vessels have been shown in solo and group exhibitions at venues including the Elmhurst Art Museum – Elmhurst, Illinois, Harvey/Meadows Gallery – Aspen, Co, Dubhe Carreño Gallery – Chicago IL, Cervini Haas Gallery/Gallery Materia – Scottsdale, AZ, Cross-Mackenzie Gallery – Washington DC, Franklin Parrasch Gallery – NYC, Santa Fe Clay – NM, The Clay Studio – Philadelphia, PA, and SOFA Chicago. His work has been presented abroad at The First World Ceramic Biennale Korea and 2010 Vallauris Biennale Internationale in Vallauris, France. Tyler’s work has been acquired by collections including the Daum Museum of Contemporary Art, in Missouri, and the Icheon World Ceramic Center in Korea. Publications including Ceramics Monthly, American Craft, Studio Potter and the Clay In Art International Yearbook have featured his work.

He has been an artist in residence at the Archie Bray Foundation and the Red Lodge Clay Center in Montana, as well as the Guldagergaard International Ceramic Research Center in Denmark. In 2010, he was one of 12 international artists invited to make and exhibit work in Walbrzych, Poland as a member of the XXXIV International Ceramics Symposium “Porcelain Another Way.” Having received his BFA from Penn State and his MFA from the New York State College of Ceramics at Alfred University, Tyler is currently a Professor teaching at Illinois State University.

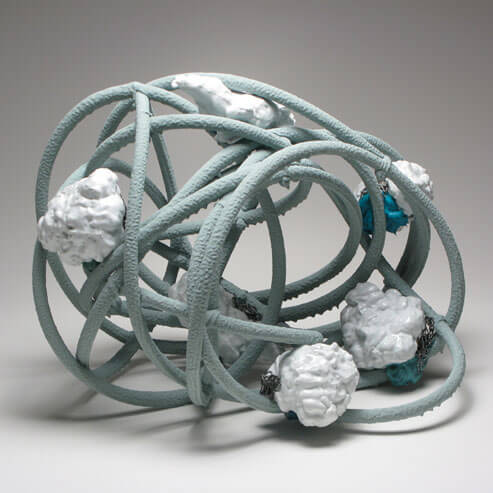

My most recent sculptures are about abstraction, a longing for wilderness, and my failed attempts at conjuring personal experiences I have had in the landscape throughout my life. Influenced by both natural and mediated landscapes, these pieces can elicit a single place and time or an amalgam of time, experiences and desires. Thus, the forms and surfaces are fragmented and residual, while simultaneously evidential and illusive. I use physical attributes of ceramic glaze like color, the range of surface between matte and gloss, and the range between translucency and opacity, coupled with a variety of application techniques to create a surface that alters our perception of the angular and organic ceramic forms. Incorporating both casting and hand forming techniques, the sculptures have the sensibility of synthetic, fabricated and built objects and environments.